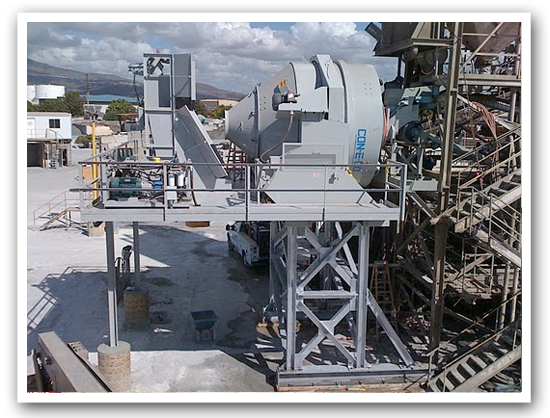

CON-E-CO Model 12 Tilt Mixer

Watch the video of the Tilt Mixer

Advantages

- Faster install and lower costs – fully assembled, wired, and plumbed

- Fast, aggressive mixing – five mixing-blade design

- Significantly reduced splashing on discharge – confinement “B” blade design

- Extended service life – 5” mixer tire and support wheels

- 14” belly band adds significant structural integrity to barrel

Features

- 12 cubic yard capacity

- Dual 75 H.P. drives

- Over-sized drum

- Mixer ships pre-assembled

- Gear-teeth clearance adjusted

- Pre-wired and pre-plumbed

- 65,000 pound heavy-duty drum, tilt frame, and stationary frame

- Machine cut, through hardened and stress-relieved ring, and pinion gears

- Machine lathed 1” thick x 14” wide ring gear band

- Top-mounted drives

- Automatic ring and pinion gear oiler

- Advanced “Five Star” mixer blade design

- 12 volt emergency tilt system

- Optional variable speed drive

- Hot dipped galvanized stairways, ladders, cages, roof railings and conveyor trusses

- Factory check out

Specifications

PRODUCTION CAPACITY

- Theoretical Cycle Time with 30 second mix time – 2 minutes

BATCHER CAPACITY

- Aggregate – 1 to 12 cubic yards (1 to 9.2 cubic meters)

- Cement – 1 to 12 cubic yards (1 to 9.2 cubic meters)

- Scales – Direct load cells

MIXER CHARGING CONVEYOR

- 48” wide (914 mm), 100 horsepower drive. Optional 54” wide (1,370 mm), 150 horsepower drive

CEMENT II FEEDER SCREWS

- 9” diameter (230 mm), 10 horsepower drive. Optional 12” diameter (300 mm), 15 horsepower drive

CEMENT AERATION

- 5 horsepower, high volume, low pressure blower

HIGH PRESSURE AIR COMPRESSOR

- 20 horsepower, 120 gallon (0.45 cubic meters) receiver. Optional 25 or 30 horsepower

ELECTRICAL

- 460 volt, 3-phase with 120 VAC transformer for control voltage. All motors are TEFC. All motor circuit wiring protected by individual circuit breakers. Electrical components housed in NEMA steel enclosures. Wiring in conduit.

BATCH CONTROL SYSTEM

- Optional fully automatic computerized batch control system.

TRANSPORTATION SYSTEM

- Rear-mounted tandem axle with eight (8) 295/75R 22.5 tires, wheels, air brakes, heavy duty spring suspension, tail and brake lights and fifth wheel rub plate with king pin

STORAGE CAPACITIES

AGGREGATE HEAPED VOLUME

- 60 to 100 cubic yards

- 46 to 76 cubic meters

CEMENT I GROSS VOLUME

- 1,600 to 2,940 cubic feet

- 45 to 83 cubic meters

CEMENT II GROSS VOLUME

- 1,600 to 4,920 cubic feet

- 45 to 83 cubic meters