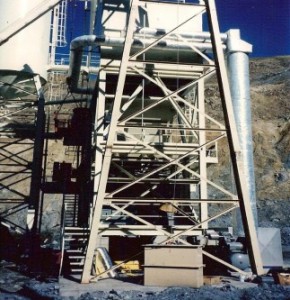

American Geothermal Air Blast Aggregate Heaters

Advantages

- Direct heat by gas-fired burners.

- Low operating costs per volume of aggregate heated.

- Reduces or eliminates the need for hot water for aggregate heating.

- Eliminates frozen materials.

- Eliminates the rusting of the plant through the use of steam and the related freeze/thaw problems.

- Optional cooling feature can provide up to a 25 degree F drop in concrete temperatures.

Features

BRIEFLY, HOW DOES THIS SYSTEM WORK?

A high volume centrifugal fan blows air across a natural gas or propane burner. The unit can either be mounted on a platform or on the ground. This heated air is ducted into the bottom of the aggregate bins. The type of air distribution is determined by the type of aggregate. The unit is capable of heating both coarse aggregate and the sand. Temperature sensors are installed to control the temperature of the aggregate. The system runs unattended.

HOW FAST CAN THE MATERIAL BE HEATED?

The material can be heated to required temperatures at rates up to 200 yards per hour.

DOES THIS METHOD PRODUCE HOT SPOTS?

No, the temperature of the air blowing on the stone can be regulated. The idea is to get large volumes of low temperature air through the aggregate.

DOES THIS PROCESS DRY OUT THE MATERIAL?

Heated dry air will dry out material. In the field we have tested the moisture drop over a one hour period to be minimal. We have also discovered that the moisture content becomes more consistent with this procedure.

IS THIS SYSTEM NOISY?

Our centrifugal fan sounds like a purr when compared to a screaming axial fan. This provides a safer working environment and less irritation to the workers.